Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

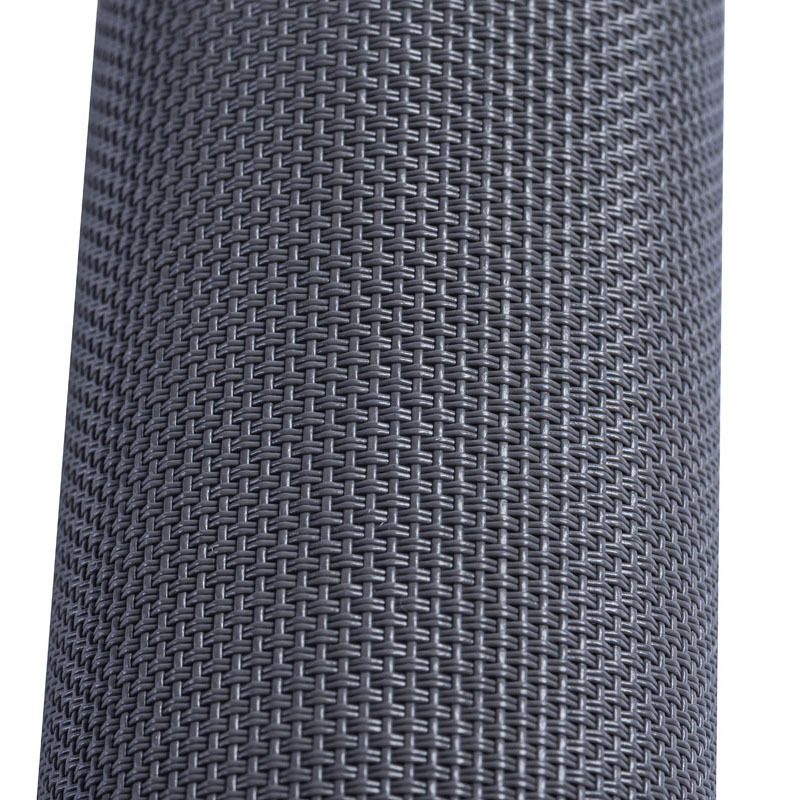

Overview of printing process of quality textiline mesh fabric

Aug 30,2022

Quality textiline mesh fabric printing is undoubtedly one of the ancient, simple and low-cost methods for making plain mesh fabrics embroidered.

Quality textiline mesh fabric printing is undoubtedly one of the ancient, simple and low-cost methods for making plain mesh fabrics embroidered. It can be used in various printing methods (direct printing, discharge printing, resist printing) and Printing technology (roller printing, flat screen printing, rotary screen printing and transfer printing) prints most of the dyes on the quality textiline mesh fabric. Different printing processes can make the mesh fabric produce different color effects. The following are Focus on common printing processes:

1. Direct printing, the simple way to print the designed pattern on the plain quality textiline mesh fabric is to print the pattern on a pre-prepared white quality textiline mesh fabric. Direct printing methods usually use paints, which are inexpensive to process.

2. Discharge printing, directly printing a piece of dyed quality textiline mesh fabric, the difference is that the background color in the printing area will be removed.

3. Anti-dye printing, the pre-prepared white quality textiline mesh fabric is chemically or mechanically printed with anti-dye paste before dyeing, which is divided into anti-white printing and color-proof printing.

4. Roller printing, which is a gravure process. It embeds the pattern on a copper plate or a light metal-coated roller. The quality textiline mesh fabric is tied up and passed on the engraved roller. It is squeezed and absorbed by the roller. The penetrating dye achieves the printing effect.

Related News